The splicing of the optical cable should be carried out in a clean environment. It is strictly prohibited to operate in the open air in a dusty and humid environment. The splicing parts, tools, and materials of the optical cable should be kept clean, and the optical fiber connector should not be damp. The optical fiber to be cut must be clean and free of dirt. After cutting, the fiber must not be exposed to the air for too long, especially in a dusty and humid environment.

Choose experienced and well-trained optical fiber splicers for splicing. Nowadays, most splicing is automatic splicing by optical fiber splicers, but the level of splicing personnel directly affects the splicing loss. The splicing personnel should strictly follow the optical fiber fusion splicing process flow chart for splicing, and during the splicing process, use OTDR to test the splicing loss of the splicing point. Those that do not meet the requirements should be spliced again. For points with larger splicing loss, the number of repeated splicing should be 3 to 4 times. When the splicing loss of multiple optical fibers is large, you can cut off a section of the optical cable and re-splice it.

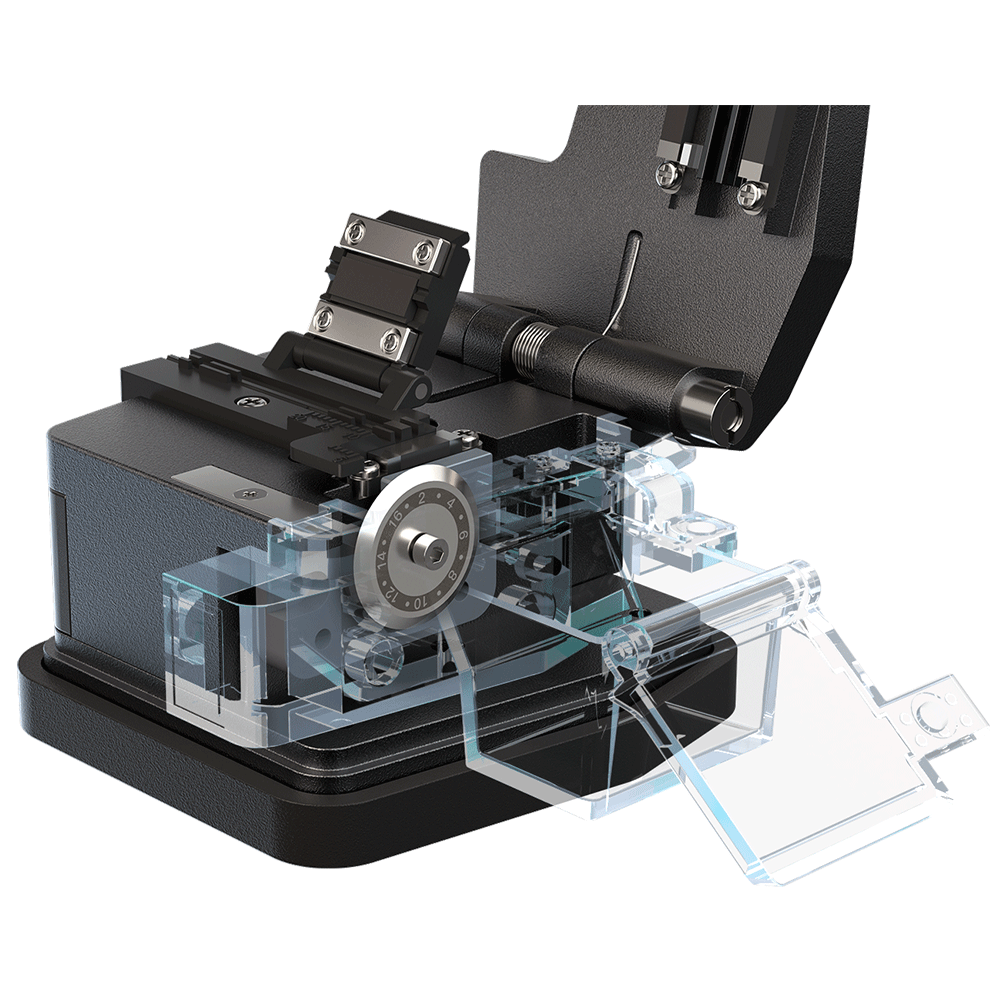

Use a high-precision fiber end face cleaver to prepare the fiber end face. The quality of the fiber end face directly affects the splicing loss. The cut fiber should be a flat mirror, free of burrs and defects. The inclination angle of the axis of the fiber end face should be less than 1 degree. The high-precision fiber end face cleaver not only improves the success rate of fiber cutting, but also improves the quality of the fiber end face. This is especially important for fusion splices that cannot be tested by OTDR (ie blind spots for OTDR testing) and fiber maintenance and repair.

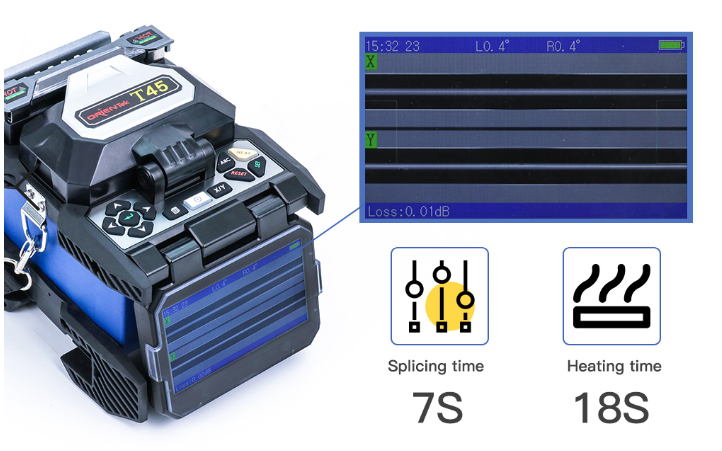

The optical fiber fusion splicer should be used correctly. The function of the optical fiber fusion splicer is to splice two optical fibers together. Therefore, the correct use of the optical fiber fusion splicer is also an important measure to reduce optical fiber splice loss. Set the splicing parameters, pre-discharge current, time, main discharge current, main discharge time, etc. correctly and reasonably according to the fiber type, and remove the dust in the fiber fusion splicer in time during and after use, especially the fixtures, mirrors and v-types Removal of dust and fiber fragments in the tank. The optical fiber fusion splicer should be placed in the fusion splicing environment for at least 15 minutes before each use, especially in places where the placement and the use environment are quite different (such as indoor and outdoor in winter), according to the atmospheric pressure, temperature, humidity, etc. at that time If the situation occurs, reset the discharge voltage and discharge position of the fiber fusion splicer, and reset the V-groove driver.

Try to use the same batch of high-quality brand-name bare fibers on a line. For the same batch of fibers, the mode field diameter is basically the same. After the fiber is disconnected at a certain point, the mode field diameter between the two ends can be regarded as the same. The disconnection point fusion can minimize the influence of the mode field diameter on the fiber fusion splicing loss. Therefore, optical fiber cable manufacturers are required to use the same batch of bare fibers to produce continuously according to the required optical cable length, serially number and distinguish A and B ends on each reel, and no number skipping is allowed. When laying the optical cable, it must be laid out in the order along the route determined by the number, and ensure that the B end of the front optical cable is connected to the A end of the next optical cable, so as to ensure that the connection can be welded at the disconnection point and the welding loss value can reach The smallest.

Optical cable erection is carried out according to requirements. In the installation of optical cable, small loops, bending and twisting of optical cables are strictly prohibited. For 3km optical cables, more than 80 people must be used for construction, and 4km must be constructed with more than 100 people, and 6-8 walkie-talkies should be equipped; , The method of laying the cable on the shoulder of the optical cable can effectively prevent the occurrence of back buckle. The traction force does not exceed 80% of the allowable fiber optic cable, and the instantaneous maximum traction force does not exceed 100%. The traction force should be added to the fiber optic cable reinforcement. The laying of the optical cable should be strictly in accordance with the construction requirements of the optical cable, so as to minimize the probability of damage to the optical fiber during the construction of the optical cable, and to avoid the increase of fusion loss caused by the damage of the optical fiber core.