First, we need to understand what a fusion splicer is. A fusion splicer is a machine that fuses or welds two different pieces of fiber optic glass cables together to become one with an electric current also known as an arc. When using a fusion splicer, most fusion splicers have an attached shrink oven that the protection sleeve is placed into to complete the process. We all know that fiber optic cables are made of glass, glass especially thin fibers, which are very brittle and easily broken. After the glass fusion is completed, this is where our friend, the fusion splice sleeves step in.

What is a fusion splice protection sleeve?

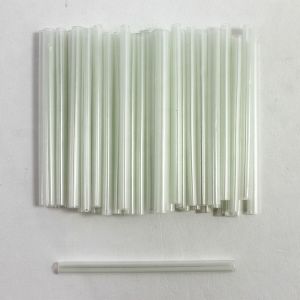

A fusion protection sleeve is used to protect the fusion splice where the two separate pieces of fiber optic cable have been joined into one. A protection sleeve is made up of three parts: An outer shrinkable tube made of heat shrink plastic, an inner tube or fiber tube where the fiber is placed, and a strength member, either made of stainless steel or ceramic. The protection sleeve ensures a consistent and reliable means of protection of the fiber when heat is applied from the splicer oven or external oven.

What are the types of fusion protection sleeves?

Fusion protection sleeves can be broken down into basically two categories: single splice protection sleeves and ribbon splice protection sleeves and will most commonly be 40mm or 60mm in length . A single splice protection sleeve is just that, a sleeve that will accommodate a single piece of fused fiber. A ribbon splice sleeve can accommodate multiple fiber splices ranging from 2-12 fibers inside the sleeve.

How to use a fusion splice protection sleeve?

Before using the splice sleeve, first the splice sleeve itself should be inspected. Make sure the sleeve isn't deformed and cleans both inside and outside the sleeve. Not cleaning your fiber optic accessories and equipment is the leading cause of attenuation in the cable. So before installing the sleeve, it is a good practice to make sure it is free of contaminates along with cleaning the fiber before installing the sleeve, as the slightest bit of contaminates could and most likely will cause attenuation.

Another factor to consider in this process is actually the type of cable you’re using to splice with. Some fiber optic cables contain a gel similar to petroleum jelly that is contained on the inside jacket of the fiber. This gel will need to be cleaned off of the cable with a special degreaser wipe to ensure the proper fit and finish of the application of the splice sleeve.

In summary, you should have some new understanding of the fiber splice protection sleeve. Although the fiber splice protection sleeve is small, it is a huge importance to the fusion splicing world of fiber optics. When all of these practices are met, you will be successful when you decide to try your hand at fusion splicing with the added protection of fusion protection sleeves added.